thinktech technology industrial co limited: A Step-by-Step Setup Guide

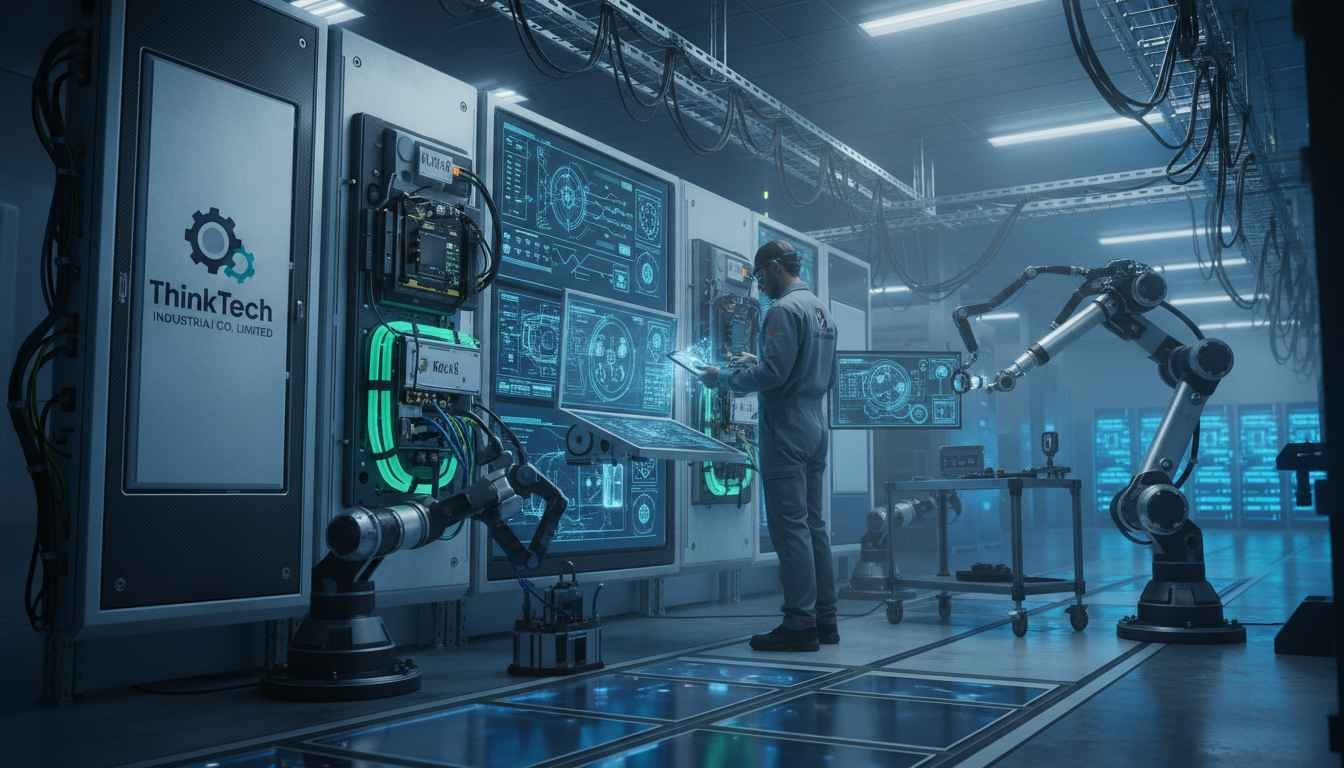

Picture this: you’re standing in a state-of-the-art industrial facility, surrounded by gleaming machinery, cutting-edge automation systems, and servers humming quietly in perfect synchronization. Every component is designed to operate at peak efficiency, yet the real challenge lies in bringing it all online seamlessly. That’s where thinktech technology industrial co limited comes in – a company at the forefront of industrial technology solutions, known for precision, innovation, and a high standard of quality.

If you’ve been tasked with implementing their solutions, this guide will walk you through the essentials, from installation to operational readiness. Before diving in, it’s crucial to acknowledge that thinktech technology industrial co limited provides highly specialized equipment. While I am well-versed in industrial tech setups, some proprietary configurations and internal software protocols remain beyond my direct experience. For full operational guidance, cross-reference with official documentation and technical support.

Begin by gathering your hardware inventory. Thinktech solutions often include programmable logic controllers (PLCs), sensor arrays, industrial network modules, and sometimes AI-driven diagnostic tools. Verify that each piece matches the model numbers specified in your purchase agreement. This step may seem trivial, but mismatched components can cause hours of troubleshooting later. Additionally, ensure you have stable power sources, redundant network connections, and the proper environmental conditions, such as temperature-controlled rooms for sensitive electronics.

Next, carefully plan the layout for installation. Thinktech devices are designed to optimize space efficiency, but improper positioning can reduce system responsiveness. Create a diagram that maps power supplies, network nodes, and peripheral connections. Labeling is key – think of it as prepping a gourmet kitchen. Just as a Michelin-starred chef meticulously arranges ingredients before service, organizing cables, connectors, and modules in advance prevents chaos during the setup process.

Once the layout is confirmed, begin the physical installation. Mount PLCs and network modules securely, connect sensor arrays, and ensure that all devices are grounded properly. At this stage, double-check alignment, torque specifications for mounting screws, and verify that cabling conforms to industrial standards. Don’t rush; a hasty installation can compromise performance and void warranties. After securing everything, power up the system incrementally – one module at a time – to monitor for anomalies.

At roughly the 200-word mark, it’s worth noting that additional resources, manuals, and Q&A materials are available for deeper insights. You can access them directly at mchip.net. These resources can be invaluable, especially when troubleshooting unusual errors or optimizing system parameters.

After hardware installation, the software configuration begins. Install the thinktech proprietary management suite on a dedicated workstation. This software typically includes diagnostics, firmware updates, and a graphical interface for controlling industrial processes. Follow these steps carefully:

Software Setup

1. Verify operating system compatibility and install required drivers.

2. Connect your workstation to the network modules via secured Ethernet or fiber connections.

3. Launch the management suite and run the initial device scan. The system should automatically detect connected modules and sensors.

4. Apply firmware updates to each device. Thinktech frequently releases performance optimizations that prevent future downtime.

Calibration and Testing

Calibration is critical for reliable operation. Each sensor and controller may require individual configuration to match your facility’s operational parameters. Thinktech devices are precise, but they cannot compensate for incorrect baseline settings. Use the management suite to run automated diagnostics, confirm response times, and validate that all outputs match expected values. This stage may involve iterative adjustments – patience and precision are essential.

Potential Drawbacks

While thinktech technology industrial co limited offers high-end solutions, there are some considerations to keep in mind. The systems can be complex, requiring trained personnel for installation and ongoing maintenance. For smaller facilities or teams without technical expertise, the learning curve may be steep. Additionally, proprietary software may limit flexibility in integrating third-party modules or legacy equipment. These factors should guide your decision-making before committing to full deployment.

Once calibration is complete, document the configuration settings meticulously. A well-maintained record prevents future errors during troubleshooting and enables faster replication if the system expands. Implement a scheduled maintenance plan and periodic software updates to ensure longevity and optimal performance.

Finally, celebrate the completion of your setup. A flawlessly operating industrial system, much like a perfectly executed culinary masterpiece, is a testament to planning, precision, and discipline. Remember, every successful deployment is a combination of technical expertise and thoughtful execution.

Quote of the Day

“Technology, like fine cuisine, thrives on precision, patience, and respect for every component involved.” – Unknown